Precipitation : Fluidized Bed Precipitation

<p>Improve the quality, flowability, and density of your concentrates while reducing transportation and production costs through fluidized bed precipitation.</p>

-

- Convert a dissolved compound into a solid product by precipitation at the end of a hydrometallurgical process.

- Overcome the limitations of conventional tank precipitation: poor flowability, low density, presence of impurities.

- Limit additional logistics costs related to transporting low-density products.

- Enhance final quality by reducing impurities in concentrates to minimize penalties and optimize marketability.

-

- Entrust your production to the fluidized bed precipitation process, a technology developed and implemented by Orano.

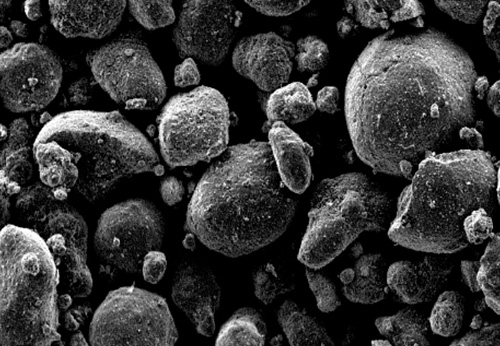

- Carry out precipitation in a vertical fluidized bed reactor, where the uraniferous solution is treated with a precipitating agent to directly form solid particles.

- Prepare a denser and more homogeneous uranium concentrate, in the form of solid particles suitable for packaging.

- Increase the density of the final product to optimize drum filling and significantly reduce transportation costs.

- Obtain free-flowing, filterable powders, facilitating packaging operations without compromising production rates.

- Reduce impurities and ensure a higher-quality product that complies with industrial standards.

-

- Good filterability: no negative impact on production rates.

- Free-flowing dry powder, suitable for packaging operations.

- High density of the dry product: optimized drum filling and significant transport savings.

- Process successfully industrialized in 2007 at Orano’s uranium facility in Kazakhstan (>4,000 tonnes/year).

- Standard Orano process for new precipitation projects, thanks to its robustness and cost-effectiveness.

- Optimized production costs compared with other conventional processes.

- Contribution to radiological safety.

- Economic advantage during product drying.

-

We have already licensed the cask in France and in Belgium for fissile content as B(U) package: Specifically developed for transport and storage of irradiated uranium residue equipped with special boron basket (fissile material)

The Innovation Center for Extractive Metallurgy or CIME from Orano Group develops scientific and technical solutions to meet the needs of its customers in the fields of energy, the environment, industrial recycling, health, minerals and ores processing and engineering.

The tripe function allows both to transport, store and dispose waste with the same cask.

-