Purification of Effluents via Membrane Separation

<p>Benefit from an innovative process to purify your water or wastewater with triple benefits.</p>

-

- Replace conventional physico-chemical processes (adsorption, precipitation, ion exchange), often costly and complex.

- Efficiently separate dissolved species of different sizes (e.g., Na⁺ and UO₂²⁺).

- Reduce operating costs associated with successive reagent-intensive and heavy process steps.

- Implement a reliable technology for purification, recycling, or drinking water production.

- Access adaptable solutions, from laboratory scale up to on-site pilot testing.

-

- Adopt an innovative membrane technology based on semi-permeable membranes.

- Separate your effluents according to species size: from microfiltration (hundreds of µm) to ions via reverse osmosis (2–3 Å).

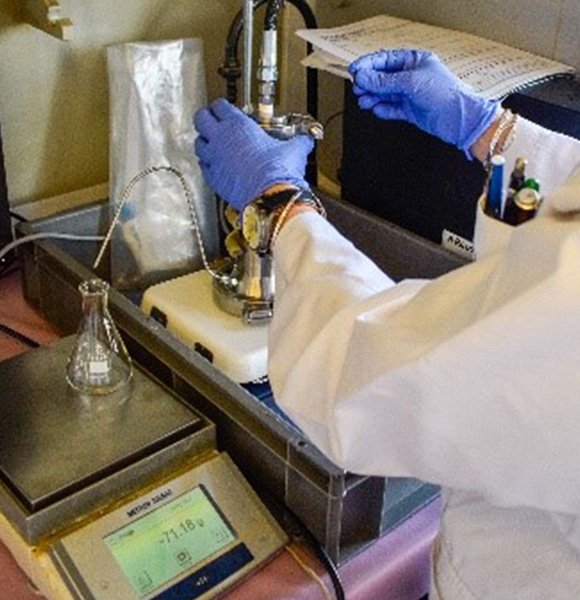

- Develop your studies from laboratory scale up to industrial pilot.

- Use a mobile pilot housed in a 20-foot container to test directly on site.

- Purify your effluents while reducing reagent consumption and simplifying your processes.

-

- Wide separation range: from particles (µm) down to ions (Å).

- Varied test formats: from 100 mL to 1 m³.

- Mobile pilot deployable on site (20-foot container).

- Removal rates >99.5% for uranium and radium (two nanofiltration membranes).

- Permeate quality below WHO guidelines: <30 µg/L uranium.

- Results confirmed under real conditions: several m³ of mine drainage water treated.

- Reduced reagent consumption and by-product recovery.

- Applied studies in mining:

- Katco (Kazakhstan): recovery of 30–60% of free acidity in the permeate and 70–98% of uranium.

- Trekkopje (Namibia): treatment of alkaline eluates, separation of uranium/sodium bicarbonate with DOW NF270 membrane.

-

-

-