Process: Solvent Extraction

Effectively recover value from co-products using a proven liquid-liquid extraction process, adaptable to complex feed matrices.

-

- Efficiently separate valuable elements from complex ores or effluents

- Identify the right extraction process based on waste characteristics and goals, whether recovery, purification, or decontamination

- Achieve high-purity final products, even from complex mixtures

- Minimize the environmental footprint of your treatment processes

-

- Implement a tailored liquid-liquid extraction process to recover or purify elements from complex matrices

- Test multiple technologies, including mixer-settlers, pulsed columns, and turbulent columns, depending on your industrial constraints

- Achieve efficient separation even for elements with similar or sensitive properties, such as close molecular structures, boiling points, or thermos-sensitivity

- Reduce solvent consumption with optimized process cycles and extractant phase regeneration

- Rely on proven support for complex industrial cases involving uranium, rare earth elements, vanadium, wastes

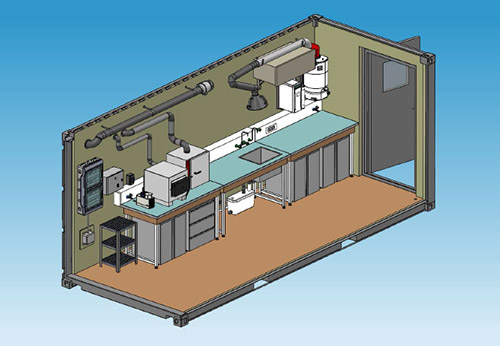

- Accelerate scale-up from lab to semi-industrial scale with flexible infrastructure and experienced teams

- Treat waste and effluent, optimize processes, and recover by-products

- Ensure only an outgoing flow from your plant

-

- Over 100,000 tonnes of uranium recovered in Niger (Somair and Cominak) using tertiary amine-based processes for selective extraction, even in the presence of impurities such as iron or vanadium

- Threefold reduction in solvent consumption through optimized extraction cycles

- Process under development for vanadium recovery

- Achieves very high purity levels, even for chemically similar elements

- Efficient treatment of high flow rates and slow reactions using proven technologies, including mixer-settlers, pulsed columns, and turbulent columns

- Modular process adaptable to a wide range of matrix types, including diverse forms, origins, and chemical complexities

- Capable of extracting nearly all elements of the periodic table, including sensitive or complex components

- Reduced environmental footprint through extractant regeneration and controlled consumption

-

-

-