Spent Fuel Reprocessing & Recycling

Strengthen your security of supply and preserve natural resources, reduce risks and long-term management costs for your high-level radioactive waste through sustainable spent fuel management.

-

- Secure the continued operation of your electricity generation by preventing the saturation of your spent fuel storage pools.

- Secure your fuel supply by reusing valuable materials, particularly in a context of geopolitical instability or constraints on the natural uranium market.

- Optimise your high-level waste management, including the design and operation of the Deep Geological disposal facilities.

- Reduce uncertainties associated with delays in deep geological disposal projects and mitigate risks associated with complex reconditioning operations for stored spent fuel.

- Strengthen public confidence in long-term waste management solutions and gain social acceptance for the increasing use of nuclear energy.

-

- Implement a safe and sustainable solution through proven industrial technologies for the treatment and recycling of spent fuel.

- Develop the circular economy by recovering up to 96% of the materials contained in your spent fuel and reduce your natural uranium requirements by up to 40% compared with the open fuel cycle.

- Strengthen your energy security by using fuels based on recycled materials.

- Reduce the volume of long-lived waste by a factor of 5 and its radiotoxicity by a factor of 10 compared with the open fuel cycle.

- Benefit from standardized, safe, and durable conditioning of long-lived waste in vitrified or compacted canisters designed for transport, interim storage, and final disposal.

- Ensure cost predictability by avoiding provisions for uncertainties inherent to open fuel cycle management.

- Further reduce the carbon footprint of nuclear electricity and its environmental impact.

-

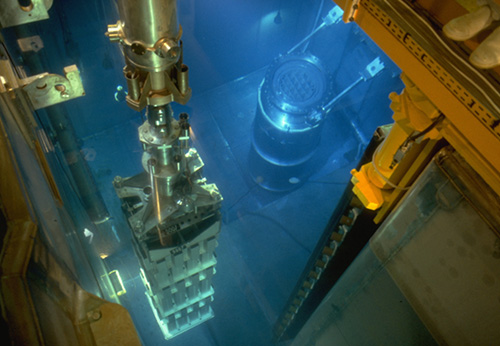

- Over 41,000 tonnes of heavy Metal reprocessed at Orano La Hague, with 96% material valorisation (uranium and plutonium) for operators such as EDF, EPZ (Netherlands), SOGIN, Synatom, as well as Swiss, Japanese, and German utilities.

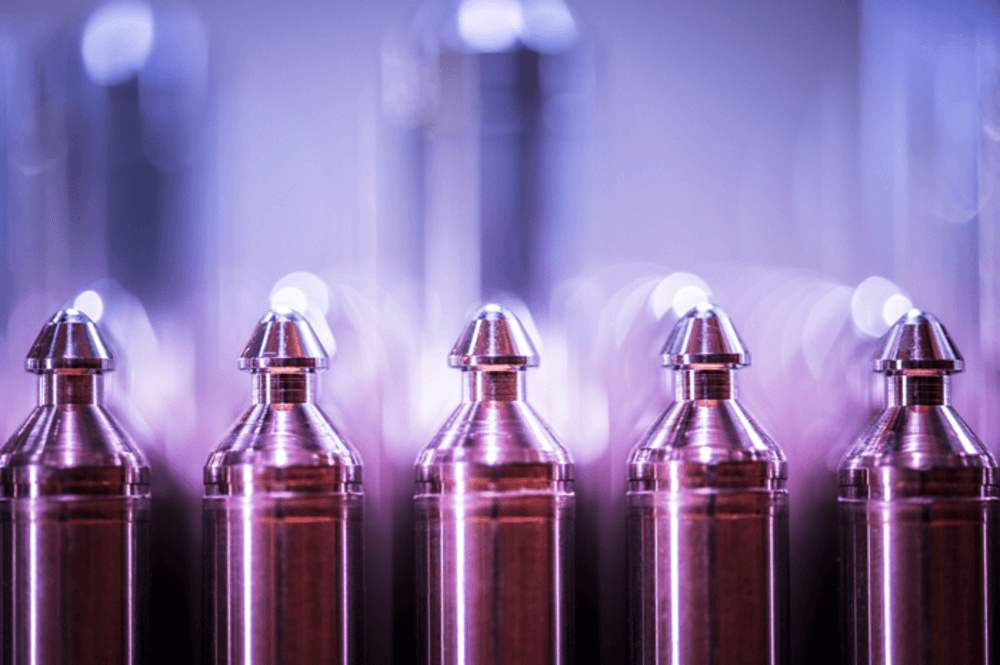

- Over 3,200 tonnes of MOX fuel produced at Orano Melox since its commissioning

- 43 reactors worldwide supplied with MOX (France, Germany, Japan, Switzerland, Belgium, Netherlands, United States).

- Manufacturing of standardized vitrified and compacted canisters ensuring safe and stable conditioning of ultimate waste, and their interim storage prior to return transport to the country of origin.

- A fully integrated and proven industrial chain mastered by Orano for more than 50 years: transport and reception of spent fuel, material separation, conditioning of ultimate waste, dedicated on-site interim storage prior to shipment, MOX fuel fabrication (recycled plutonium + depleted uranium), and, if desired, URE fuel assembly fabrication through partners.

-