Waste Cementation: from Study to Implementation of Pilot Trials

<p>Secure the conditioning of your VLLW (Very Low-Level Waste) or LLW-IL (Low- and Intermediate-Level Waste, Short-Lived) radioactive waste through an innovative cementation process.</p>

-

- Condition your radioactive waste to enable safe storage.

- Select a matrix suited to the specific characteristics of your waste.

- Meet regulatory acceptance criteria (ANDRA, ASN, etc.).

- Use a reliable and cost-effective process implemented at ambient temperature.

- Reduce risks associated with the chemical stability and ionizing radiation of LLW-IL waste.

-

- Develop tailor-made cement formulations adapted to your waste and compliant with current regulations.

- Benefit from Orano’s R&D expertise and CIME’s know-how to stabilize and solidify your waste.

- Validate your technical choices through laboratory tests with inactive wastes (potentially containing Uranium or Thorium), complemented by pilot-scale trials.

- Ensure reliable and compliant conditioning that incorporates both the specific nature of your waste and your storage constraints.

- Rely on a comprehensive approach: study, characterization, formulation, piloting, and commissioning.

-

- Cost-effective process: implemented at ambient temperature with low-cost raw materials and mixing operations.

- Chemical compatibility: cement formulations suited to most nuclear industry wastes.

- Wide choice of matrices:

- Portland cements (with or without mineral additions)

- Phosphate–magnesia cements (Malvési sludges)

- Calcium aluminate cements (La Hague sludges)

- Geopolymers (ion-exchange resins)

- Flexibility: formulations adapted to your specific technical and regulatory constraints.

- Proven experience: numerous projects conducted on sludges, effluents, and radioactive resins.

- Dedicated laboratory for cementation studies using inactive matrices simulating active waste (Uranium, Thorium).

- Full range of equipment to study stabilization capacity, perform in situ analyses, and ensure encapsulated waste quality monitoring.

- Semi-industrial pilot unit: continuous cementation facility (10 L/h).

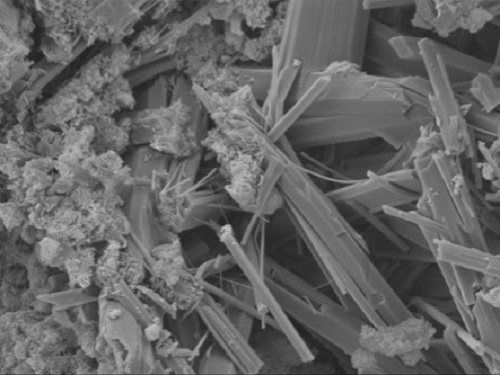

- Complementary analyses: SEM, XRD, pore solution chemistry for ANDRA qualification files.

- Guaranteed compliance: conformity tests on encapsulated specimens to validate compliance with ANDRA specifications.

-

-

-