Process: Separation by Ion Exchange Resins

<p>Access a selective and cost-effective process that enables you to separate and purify your metals, even at trace levels.</p>

-

- Improve the purity of your metals with a hydrometallurgical process.

- Eliminate impurities present in your leach solutions.

- Recover and valorize strategic metals, including from by-products.

- Reduce processing costs by replacing or complementing complex chemical steps.

- Rely on a process adaptable to different metals and concentration ranges.

-

- Implement a process based on ion-exchange resins that ensures selective and efficient metal separation.

- Purify your leach solutions by eliminating undesirable elements that degrade metal quality.

- Recover your target metals, even at trace levels.

- Easily adapt the process to your needs thanks to three mastered IX technologies (RIP, fixed bed, CIX).

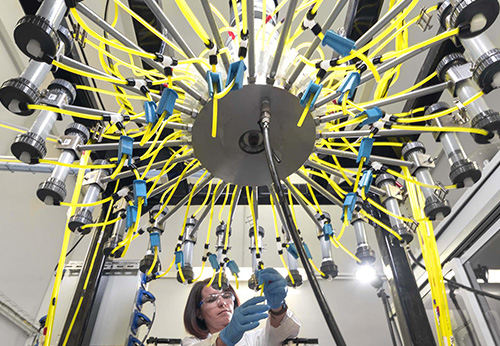

- Optimize your processes using resins composed of fine particles that allow rapid exchanges and short equilibrium times.

-

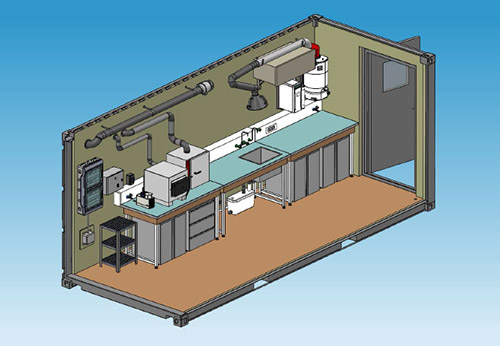

- Three IX technologies operated at CIME: RIP, fixed bed, CIX.

- Wide concentration range treated: from a few mg/L up to 500 mg/L.

- Flexible operation: from 100 mL/h to several L/h.

- High-performance resins: fine particles for fast exchanges and short equilibrium times.

- International experience: R&D trials and column sizing for the uranium plant in Kazakhstan and an industrial pilot in Mongolia.

- Valorization of uranium recovered as a by-product from phosphates or sulfate/chloride effluents.

- Recovery and valorization of strategic elements: rhenium, molybdenum, gold, uranium.

- Wide applications: water treatment, decontamination of radioactive effluents, extraction of heavy metals (cadmium, chromium), fixation of ²²⁸Ra and production of ²¹²Pb.

- Mastery of IX process development steps: batch tests (isotherms, continuous columns) followed by pilot-scale trials.

- Development of new resins tailored to specific needs.

-

-

-