Skid Containers: Tests and Laboratory for On-Site Piloting

<p>Carry out your tests and pilot operations directly on site with mobile skid-mounted containers and validate your processes under real industrial conditions.</p>

-

- Validate your processes on real matrices, not only on simulants.

- Test your solutions efficiently without requiring dedicated on-site infrastructure.

- Reduce uncertainties linked to impurities or complex parameters in your effluents and ores (suspended solids, ore fines, viscosity, impurities).

- Limit the risks associated with transporting sensitive materials.

- Collaborate closely with a technical partner capable of quickly adapting to your needs.

-

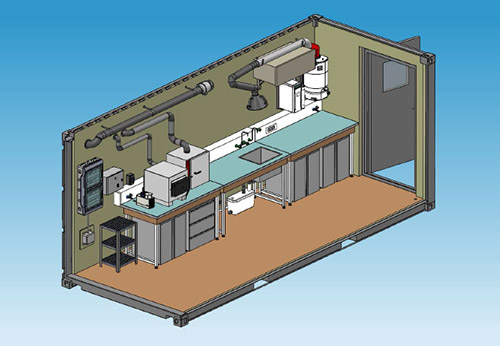

- Access two mobile 20-foot ISO containers designed for your trials: one pilot skid and one laboratory.

- Conduct your tests directly on site, considering all real constraints (impurities, viscosity, suspended solids, high acidity).

- Benefit from total flexibility: more than ten technologies can be integrated depending on your needs (leaching, solid-liquid separation, SX, IX, precipitation).

- Develop your process flow sheets step by step, from bench-scale trials to continuous pilot operations.

- Work in close collaboration with your teams, enabling fast adaptation to evolutions and efficient co-development.

- Secure your trials with the potential support of CIME’s analytical laboratory for complex studies.

-

- Two 20-foot ISO containers: one laboratory and one pilot skid.

- Flow rate range: from 20 mL/h to several L/h.

- More than ten technologies integrable into the skids.

- Custom adaptation according to testing needs and analytical monitoring requirements.

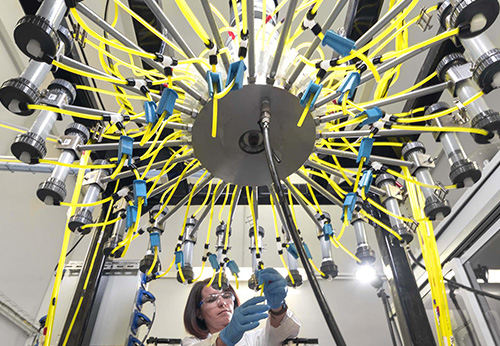

- Modular skid equipment: 4 ventilated removable units with stainless-steel structures for mixers-settlers, stirring motors, etc.

- Continuous pilot operation possible: 3×8 h or 5×8 h shifts monitored by technicians.

- Integrated laboratory: demineralized water station, ventilation, compressor, vacuum pump, additional equipment (portable XRF, colorimeter, turbidimeter, thermogravimetric balance, densimeter, titrator, etc.).

- Proven robustness: air treatment (VOC filters), air conditioning/heating adapted to weather conditions.

- Enhanced safety: reduced chemical and radiological risks related to transport.

- Compliance with environmental and safety standards.

- Capability to perform tests on real matrices.

-

-

-