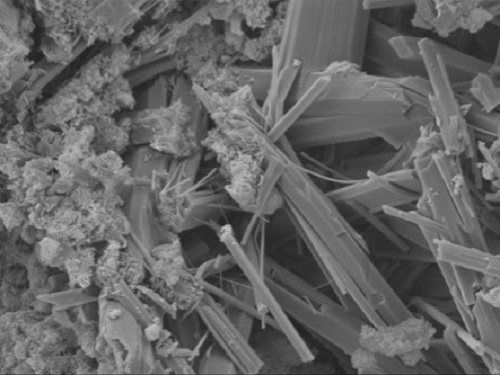

Production of Co-Precipitated Sludge

<p>Optimize your radioactive waste treatment processes by testing them on non-active sludges, representative of your various effluent types, reproducible, and tailor-made to meet your specific needs.</p>

-

- Test your chemical coprecipitation processes with reliable, representative sludges that mimic your waste streams.

- Optimize your treatment flow sheets before deployment on real active matrices.

- Assess the chemical stability and trapping capacity of the sludges produced.

- Guarantee the reproducibility and traceability of your production batches.

-

- Produce tailor-made complex sludges, adapted to your projects and representative of your waste.

- Benefit from a flexible and robust pilot unit, allowing adjustment of operating parameters to reproduce different types of sludges.

- Validate your processes by first producing small test quantities before scaling up to larger volumes.

- Ensure rigorous analytical monitoring throughout the manufacturing process to characterize the solution, the performance of sorbents, and their sorption capacity.

-

- Flexible pilot operation: variation of operating parameters to reproduce diverse sludge types.

- Stepwise production: validation on small batches before larger-scale manufacturing.

- Guaranteed reproducibility: comparable batches from one production run to another.

- Integrated specific studies: chemical stability during precipitation, sorption capacity of selected sorbents.

- Monitoring equipment: in-house analytical services for real-time solution characterization and sludge quality control.

- Proven applications: representative sludge production for the STE2 facility (five different formulations tested).

- Robust pilot unit ensuring production continuity.

- Post-production sludge treatment: solid-liquid separation equipment (filter press, centrifugation, geomembrane, etc.).

- Aging studies of sludges.

- Definition of operating parameters to guarantee future production under conditions representative of industrial reality.

- Production capacity: 150 L of coprecipitated sludges at 300 g/L.

-

-

-