Safely Condition Radioactive & Special Waste through Cementation

Produce a stable, safe, cemented conditioning suitable for the final disposal of your waste.

-

- Select a cementation technology suitable for a wide range of irradiating waste types (liquids, solids, sludges, ashes, and reactive metals), including those with specific chemical constraints

- Ensure that cemented waste packages comply with disposal route requirements and regulatory expectations

- Design a reliable and efficient facility tailored to industrial constraints and objectives

-

- Benefit from a turnkey solution for cementation-based conditioning of ILW/LLW, covering formulation, qualification, engineering, and commissioning

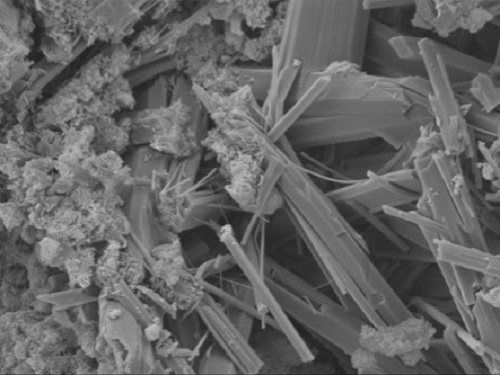

- Develop customized cement matrices adapted to the nature of your waste (such as resins, legacy waste, sludges, or reactive metals)

- Integrate an optimized process into your operational environment and objectives meeting mechanical, chemical, and radiological requirements for final disposal acceptance

- Rely on Orano’s expertise to support regulatory compliance documentation and interactions with safety authorities

- Reduce operational risks through proven, operable technologies adapted to the diversity of ILW/LLW waste streams

-

- Proven solutions for operational, legacy, and decommissioning and remediation waste including solids, liquids, sludges, ashes, reactive metals, and resin concentrates

- Patented matrix available for the neutralization of specific contaminants such as mercury

- Full process validation: lab-scale testing, 200 L and 1000 L prototype trials, and mechanical, chemical, and radiological qualification

- Cementation technologies tailored to industrial goals including batch mixers, continuous flow systems, or disposable-blade mixers

- Dedicated research facility for the development and qualification of cement matrices (TRL 1 to 8)

- Integrated approach from design through to industrial commissioning

- Customer references in France and internationally : Orano, CEA, waste disposal operators…

-

-